LVT SPC Production

LVT SPC Floor tile Production

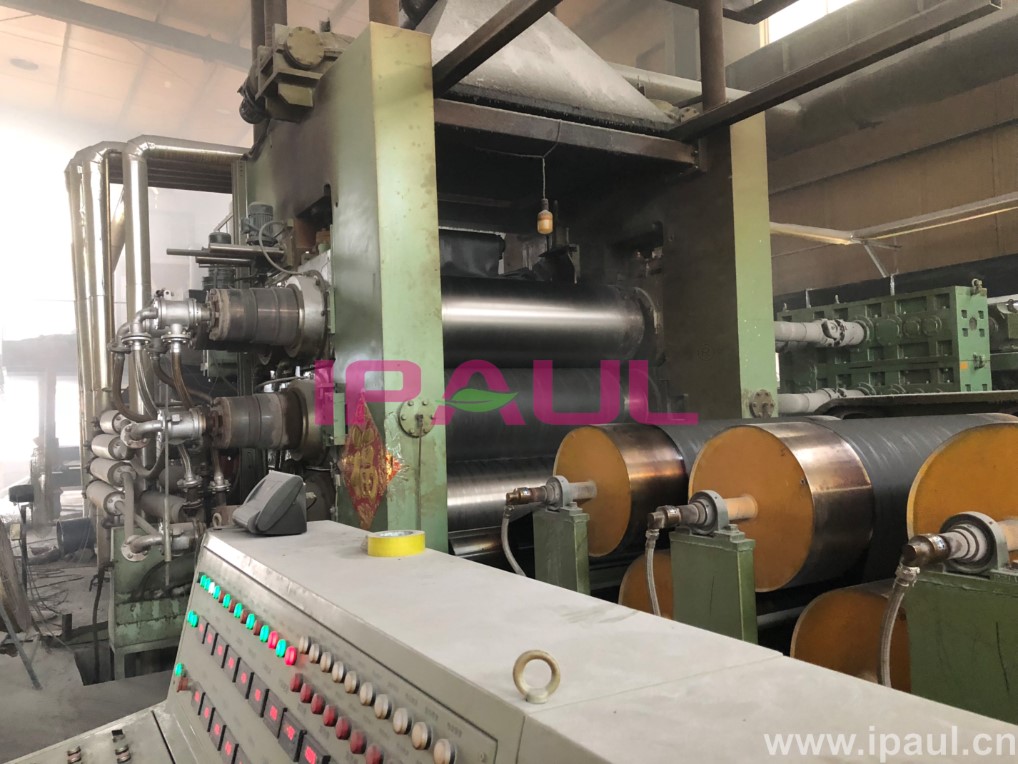

IPAUL invest a new factory in 2016, and it start production in 2, 2017. It provide customer different types of Luxury vinyl tile flooring with different texture, such as wooden texture, carpet tile texture, marble styles. It is built to the developing PVC tile foor market in domestic and abroad.

We share some photos of production here for your better learning about our products and produciton.

Vinyl floor printed film is the most important raw material for the production. We have several hundred thousands sqaure meters of stock for the most welcome colors in our cataglogue. This can reduce a lot of the production time. The new color of film need 15 days production. In fact, the tiles just need 5 ~10 days production.

Wear Layer is important for the vinyl floor tile. It provide a good protetion of the color of film. It have different thickness: 0.1mm, 0.2mm, 0.3mm, 0.5mm according to the requirements of customer.

The tile can be chamfered if required by customer. It is normally above 5mm thick and the wear layer above 0.5mm.

The QA should check the accuration of the size and flexbility during the production. Some tiles will be taken away to do some test to check the quality every cycled time.

The tiles will be package with cartons. The carton leave one space to open for better manager of the color and quality management.

The cutting edge of the panel will be recycled.

The cutting edge will be crush and make into powder, it will be used the dry back viny floor tile.

The vinyl floor tiles will be packed with pallets and stock in warehouse for delivery.

During the production, there will be much dust. so it will be collected by special enviromental machine and recycled. This is important to keep a clean production enviroment and produce less pollution.